Wholesale Discount Wood Sawdust Dryer - Air FLow Pipe Dryer – Shindery

Wholesale Discount Wood Sawdust Dryer - Air FLow Pipe Dryer – Shindery Detail:

This kind of dryer is mainly used to prepare suitable moisture raw material for biomass pellet press. It is only to control the moisture of raw material at a reasonable range that can make good result of biomass pelletizing. Or the pellets will be broken because of too loose or too dry.

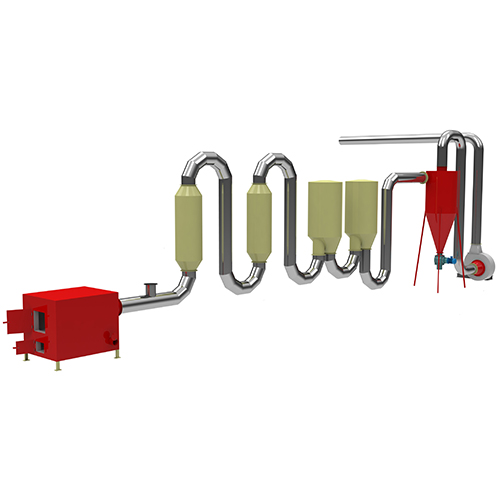

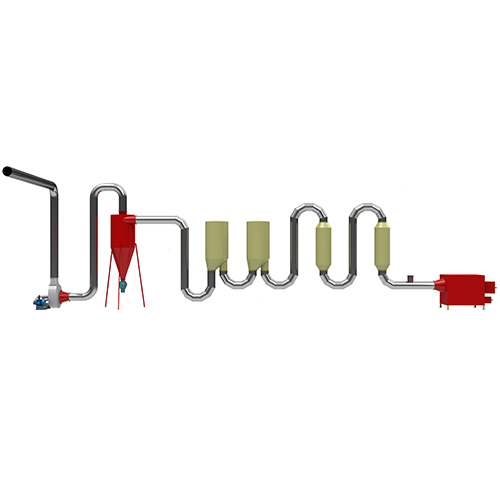

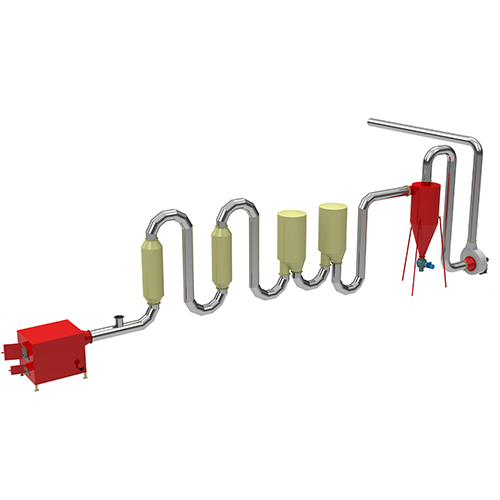

The whole system consists of fan blower, motor engine, fuel boiler, steel pipe, cyclone and air lock. In this system, wet material is input into hopper by screw feeder. Fuel furnace produces large volume of hot air. Those hot air is driven into steel pipes, mixed with wet sawdust and moved through curving pipes and drying chamber by the power of fan blower. Fast moving hot air sustains and is mixed with raw material sent by spiral feeder in the suspending state through the steel pipe; moisture evaporates as the material traverses along the steel pipe and is rendered dry at the discharge end. Humid air is continuously exhausted, thus the material is dried.

|

Model |

QHJ-1 |

QHJ-2 |

|

Dimension of Stove (m) |

1.1*1.0*1.0 |

1.5*1.2*1.2 |

|

Dia of Pipe (mm) |

219 |

325 |

|

Dia of Cyclone (mm) |

600 |

1000 |

|

Dia of Small Buffer Silo (mm) |

- |

636 |

|

Dia of Big Buffer Silo (mm) |

580 |

950 |

|

Induced Draft Fan (kw) |

5.5 |

11 |

|

Speed Adjustable Screw Feeder (kw) |

1.5 |

1.5 |

|

Total Length (m) |

11.8 |

14.6 |

|

Total Weight (t) |

2.2 |

3.2 |

|

Capacity (kgs/h) |

300-500 |

800(totally 2 small buffer silo and 2 big buffer silo,can be combined freely to realize biggest capacity or best drying effect.) |

Sawdust air flow pipe dryer

Product detail pictures:

Related Product Guide:

Emma Stone, Timothee Chalamet on how they dealt with young fame | Efb Pellet Machine

How much would it cost to build a wood pellet plant? | Mobile Hammer Crusher

Responsible excellent and fantastic credit rating standing are our principles, which will help us at a top-ranking position. Adhering towards the tenet of "quality initial, buyer supreme" for Wholesale Discount Wood Sawdust Dryer - Air FLow Pipe Dryer – Shindery , The product will supply to all over the world, such as: Germany , Manchester , El Salvador , Our products have won an excellent reputation at each of the related nations. Because the establishment of our firm. we've insisted on our production procedure innovation together with the most recent modern day managing method, attracting a sizable quantity of talents within this industry. We regard the solution good quality as our most vital essence character.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.