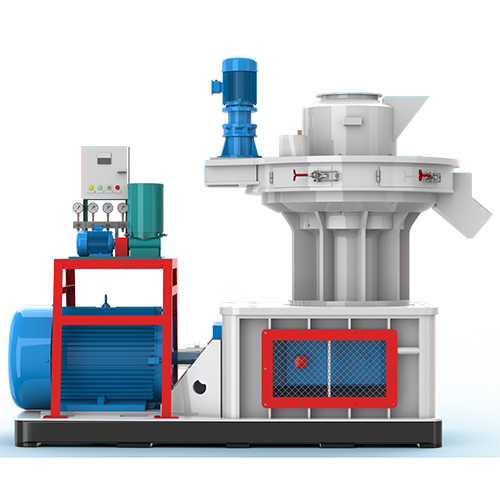

OEM/ODM Manufacturer Sawdust Pellet Mill - LGX560 Biomass Pellet Machine – Shindery

OEM/ODM Manufacturer Sawdust Pellet Mill - LGX560 Biomass Pellet Machine – Shindery Detail:

INTRODUCTION

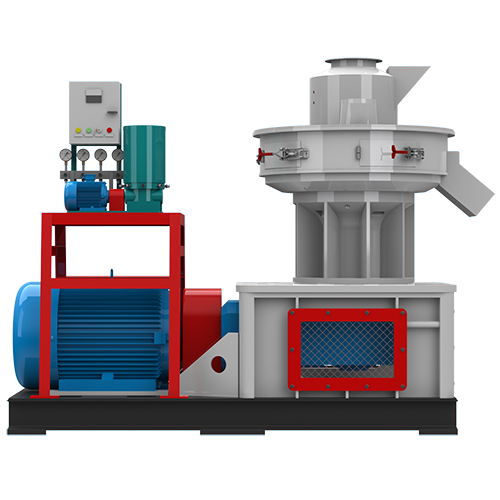

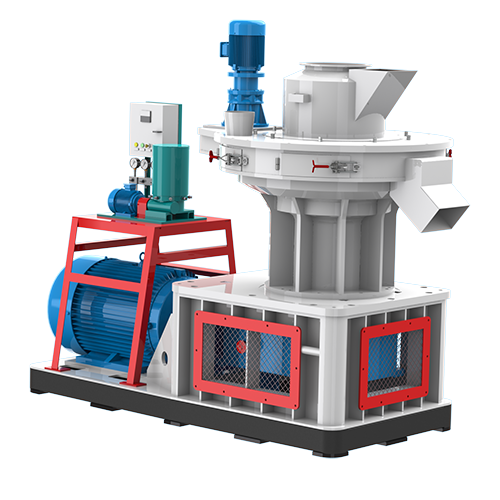

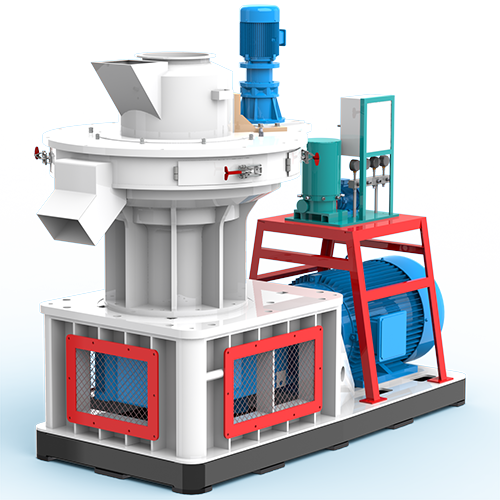

LGX-560 vertical ring die pellet machine absorbs the quintessence of various pellet machines both at home and abroad, the heart part adopts “double-layer die” as the unique structure. The rollers are made by abrasion-proof alloy steel, this pellet mill with characteristics of unique design, rational structure, lower power consumption, high efficiency, long lifetime. This machine is our initiative patent products in China through meticulous research and development, supplying the gap of vertical feeding ring-die pellet mill at home, reaches the international advanced level.

RAW MATERIAL

The equipment is applied to the material with low adhesiveness and low shaping ,such as the rice husk, sunflower seed husk, peanut shell and other fruit shell branch, trunk, bark and other wood waste; a variety of crop straws, rubber, cement ,ash and other chemical materials. The pellet mill is widely used in the feed plant, wood processing, fuel plant, fertilizer plant and chemical plant etc. It is the ideal pressing shaping equipment with low investment and high profit.

SEVEN CHARACTERISTICS

1.Feeding vertically and directly to pelletizing room.

2.Die static, rollers rotating, materials centrifugal, evenly distributed around.

3.Double-layer dies, up and down dual use, high capacity and energy saving.

4.Ring die, vertical structure, conducive to the pelletizing room cooling.

5.Independent output device, ensure formation rate of pellets.

6.Independent lubrication system, bring precise & automatic lubrication to bearings.

7.Feeding system is equipped with inverter which can bring stepless adjustable feeding speed.

|

Model |

LGX560 | |

| Power (kw) |

Main machine |

90 |

|

Pellet pusher |

1.5 | |

|

Lubrication pump |

0.37 | |

| Rotation speed (r/min) | 1450 | |

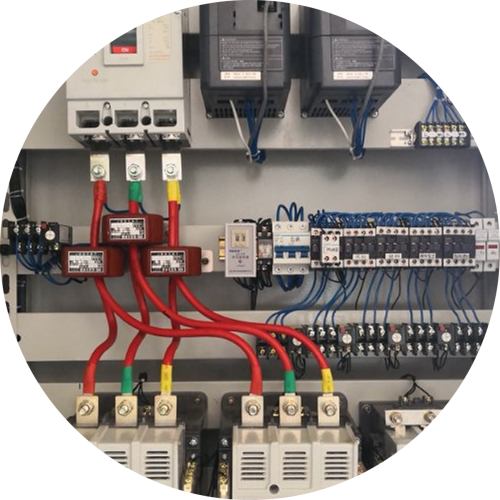

| Voltage (v) | 380 / customized ,3phase | |

| Pellet size (mm) | 4-12 | |

| Machine weight ( t ) | 5.6 | |

| External dimension (mm) | 2690*1250*2040 | |

| Ring die inner diameter (mm) | 560 | |

| Capacity (t/h) | 1.2-1.5 | |

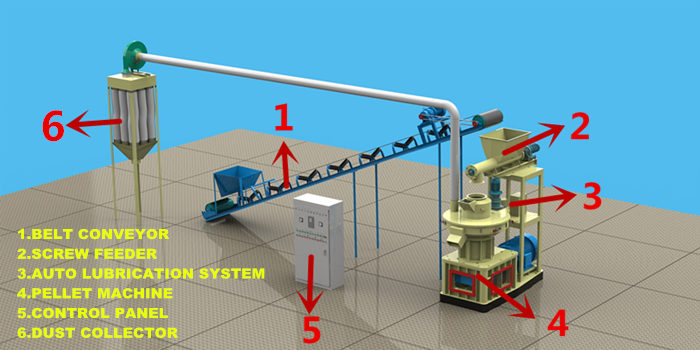

How does LGX560 ring die wood pellet machine work?

Product detail pictures:

Related Product Guide:

The Art of Biomass Pelletizing | Mobile Hammer Crusher

Even Thor Couldn’t Pick Up This Mjolnir PCMagLogo.2016 Arrow_Path | Hickory Wood Pellet Machine

Our corporation has been specializing in brand strategy. Customers' gratification is our greatest advertising. We also source OEM company for OEM/ODM Manufacturer Sawdust Pellet Mill - LGX560 Biomass Pellet Machine – Shindery , The product will supply to all over the world, such as: Guatemala , Kenya , Paraguay , There are advanced producing & processing equipment and skilled workers to ensure the products with high quality. We have found an excellent before-sale, sale, after-sale service to ensure the customers that could rest assured to make orders. Until now our products are now moving on fast and very popular in South America, East Asia, the Middle east, Africa, etc.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.