Welcome to our company websites!

News

-

What machines are needed to produce biomass pellet fuel?

The production process of biomass pellet fuel needs to be customized according to the specific situation of each customer,and the required equipment also needs to be configured according to the detailed situation. The reason for this situation is that each customer’s raw materials are diffe...Read more -

How to operate and maintain the drum wood chipper?

Do you know how to operate and maintain the drum wood chipper? 1.To fully exert the performance of the drum wood chipper,the operators should not be less than 2 people; 2.There must be no iron,stone or other impurities in the raw material; 3.When machine working,properly adjust the feed amount o...Read more -

How to dry sawdust form material with low investment and high efficiency?

The working principle of airflow pipe dryer is to let wet raw materials mix with the high temperature airflow,and finally the water is separated from the raw material through the separator.The air flow pipe dryer is widely used in biomass/wood pellet fuel production,animal feed,chemical,mining an...Read more -

Wood-Pellets Market 2019 Production (K Units), Revenue (Million USD), Market Size, Competition by Manufacturers

Wood pellet is a solid fuel that is produced by crushing and densifying waste timber like sawdust, forestry residues, industrial byproducts like old paper and forestry wastes. The length is 1-2 cm and the diameter is generally 6, 8, 10, or 12mm. It is possible to produce 25mm wood pellet at maxim...Read more -

Four Sets of Wood Hammer Crushers To Moldova

The wood sawdust hammer crusher also called wood sawdust making machine is widely used in crushing wood scraps, branches, wood chips,wood veneer, bark, bamboo and all kinds of crop stalk, cotton,firewood,straw,peanuts shells, cotton seed etc.After this equipment processing, the final sawdust is v...Read more -

Customer from Argentina visited factory & ordered machines

This customer from Argentina,he is a mechanical engineer himself,have his own business in Italy. His customer wanted to build a wood pellet factory,he was commissioned to inspect and purchase machines. He found our factory from the website,after learmt about his requirements,we provided him detai...Read more -

3T/H Acacia Wood Pellet Making Line To Guangxi

The raw material is acacia wood,a kind of hard wood. The whole line was designed with the following process. 1.DISC WOOD CHIPPER The disc wood chipper is used to chip wood log into wood chips for easily drying and crushing. 2.NEW MODEL ROTARY DRYER MACHINE To dry wood chips into ideal temperature...Read more -

Unique Design Rotary Dryer For Wood Chips Making Factory

This customer is an exporter of wood chips. The wood chips should be dried to ideal moisture for convenient storage and transportation. Our rotary dryer machine with two technological innovations1.Inner sleeve structure, significantly improve the utilization of hot airflow in the drum; 2.subverti...Read more -

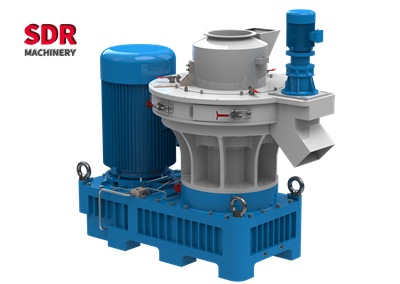

Typical Characteristics of Shindery LGX600A Model Biomass Pellet Machine

Besides with all the characteristics of traditional vertical structure ring die pellet machine, LGX600A has extra advantages as following: 1.Main transmission part adopts TONGLI brand reinforced reducer specially designed & manufactured for pellet machine with features of much higher transm...Read more -

Wood Chips Pellet Making Line For Hunan Customer

Raw material is sawdust mix with wood chips The whole line was designed to equip a rotary screener to screen out the wood chips in sawdust. After selection,the wood chips can be feed into crusher machine to crush into sawdust and feed into pellet machine. During crushing process,the raw material ...Read more -

LGX560 Pine Wood Pellet Machine Delivered To Thailand

This customer is a wood pellet fuel exporter in Thailand,he used flat die pellet machine to make pellet fuel. As he said,he had to shut down every day to troubleshoot,which has a great impact on productivity. After investigation, he realized that the flat-die pellet machine is mostly used to prod...Read more -

Wood Sawdust Making Machine,Wood Pellet Making Machine Delivered To Plywood Factory in Gabon

This customer has a plywood factory. In the production process of plywood ,a lot of waste scraps material will be produced. He was looking for ways to recycle these waste scraps materials,finally,he found us. We advised him to crush these materials and make wood pellet fuel. The final wood pellet...Read more