In December 2019, our installers returned from Romania and successfully completed the installation and commissioning of a full-scale beech & hornbeam wood pellet production line with an output of 4-5 tons per hour.

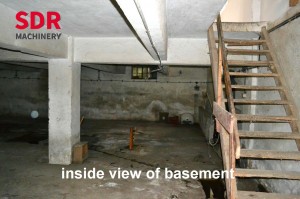

During the installation process, because the customer’s factory building was not a standardized workshop, but the private house was converted into a workshop for use, which brought a lot of difficulties to the design and installation of the entire production line. The customer’s factory building is a two-storey building with an attic, and the equipment is mainly arranged in the basement and the ground floor.

The real picture of the customer’s factory building is as follows:

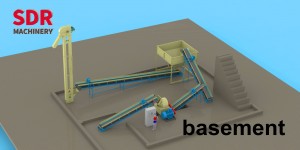

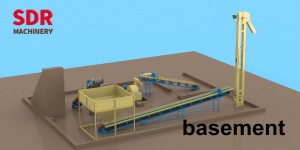

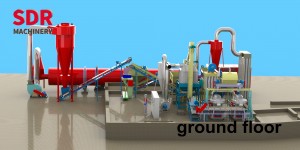

During the early communication with the customer, our engineers finally solved a variety of problems according to the detailed drawings and requirements of the plant provided by the customer, combined with years of practical experience, and creatively designed a simple and practical solution for the customer. This solution was submitted to customers in the form of 3D illustrations and detailed floor plans, which facilitates customers’ preliminary preparations.

Customer’s raw materials are mainly beech and hornbeam logs from forest with diameter not exceeding 400mm, the whole production line includes wood log chopping,drying,crushing,pelletizing,cooling and packing. Main equipments are:

1 set of SDC1500 model disc wood chipper

1 set of Dia1.6*16 model sleeve type high efficiency wood chips dryer

1 set of SGH700*1000 model hammer crusher

2 sets of LGX600 model wood pellet mills

1 set of SKLN-6 model wood pellet counter flow cooler

1 set of DCS-Z-S-50 model wood pellet packing machine

And belt conveyors, bucket elevators & electric cabinets

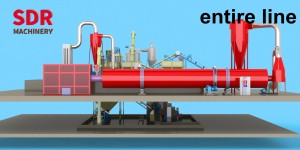

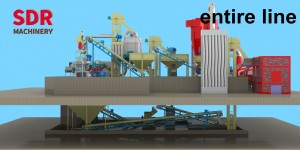

The detailed 3D design scheme is as follows:

After the equipment arrives at the customer’s site, the customer first puts the main equipment in place. Nearly at same time, we send engineers to Romania to install and debug the equipment and train it.

On-site installation situation:

After nearly two months of hard work, all the installation, commissioning and training were completed. Our engineers’ professional, rigorous and efficient working methods won high praise from customers. The engineers returned to China on December 14. At present, the complete line runs smoothly, producing 4-5 tons of high-quality wood pellets per hour, mainly for the German market.

For live video, please click below:

Post time: Jan-28-2020