Manufacturing Companies for Peanut Shell Pellet Machine - Air FLow Pipe Dryer – Shindery

Manufacturing Companies for Peanut Shell Pellet Machine - Air FLow Pipe Dryer – Shindery Detail:

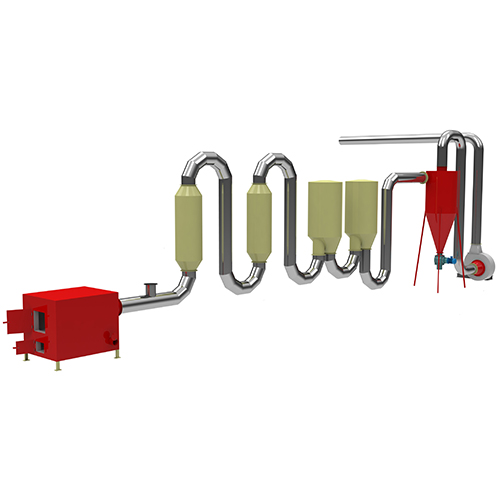

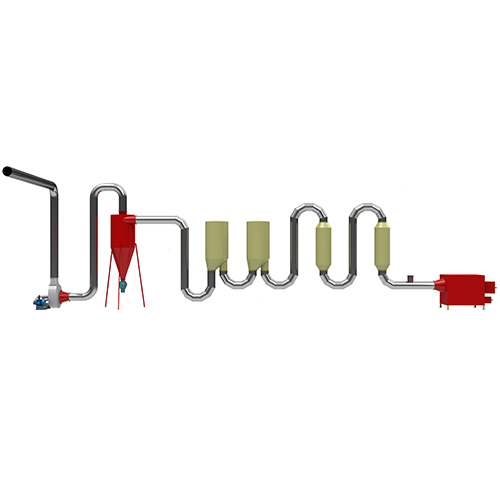

This kind of dryer is mainly used to prepare suitable moisture raw material for biomass pellet press. It is only to control the moisture of raw material at a reasonable range that can make good result of biomass pelletizing. Or the pellets will be broken because of too loose or too dry.

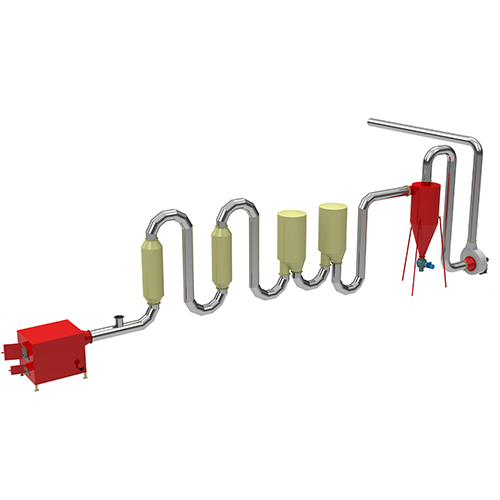

The whole system consists of fan blower, motor engine, fuel boiler, steel pipe, cyclone and air lock. In this system, wet material is input into hopper by screw feeder. Fuel furnace produces large volume of hot air. Those hot air is driven into steel pipes, mixed with wet sawdust and moved through curving pipes and drying chamber by the power of fan blower. Fast moving hot air sustains and is mixed with raw material sent by spiral feeder in the suspending state through the steel pipe; moisture evaporates as the material traverses along the steel pipe and is rendered dry at the discharge end. Humid air is continuously exhausted, thus the material is dried.

|

Model |

QHJ-1 |

QHJ-2 |

|

Dimension of Stove (m) |

1.1*1.0*1.0 |

1.5*1.2*1.2 |

|

Dia of Pipe (mm) |

219 |

325 |

|

Dia of Cyclone (mm) |

600 |

1000 |

|

Dia of Small Buffer Silo (mm) |

- |

636 |

|

Dia of Big Buffer Silo (mm) |

580 |

950 |

|

Induced Draft Fan (kw) |

5.5 |

11 |

|

Speed Adjustable Screw Feeder (kw) |

1.5 |

1.5 |

|

Total Length (m) |

11.8 |

14.6 |

|

Total Weight (t) |

2.2 |

3.2 |

|

Capacity (kgs/h) |

300-500 |

800(totally 2 small buffer silo and 2 big buffer silo,can be combined freely to realize biggest capacity or best drying effect.) |

Product detail pictures:

Related Product Guide:

Curragh Mine, Queensland | Hickory Wood Pellet Machine

Clean Harbors COO talks about the company’s evolution | Sawdust Pelleting Machine

Our pursuit and firm aim should be to "Always fulfill our buyer requirements". We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for Manufacturing Companies for Peanut Shell Pellet Machine - Air FLow Pipe Dryer – Shindery , The product will supply to all over the world, such as: El Salvador , Hongkong , Austria , During the short years, we serve our clients honestly as Quality First, Integrity Prime, Delivery Timely, which has earned us an outstanding reputation and an impressive client care portfolio. Looking forward to working with you Now!

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!