Manufactur standard Mobile Wood Shredder - Counter Flow Cooler – Shindery

Manufactur standard Mobile Wood Shredder - Counter Flow Cooler – Shindery Detail:

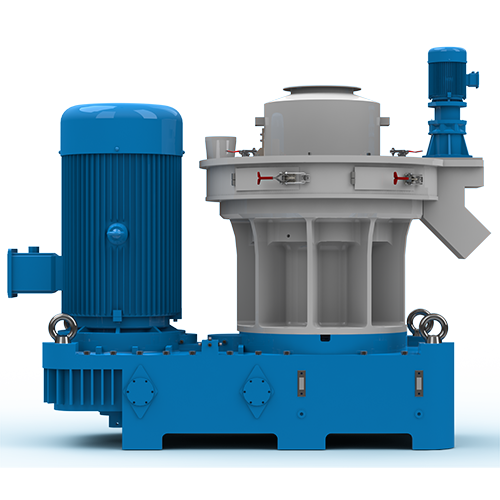

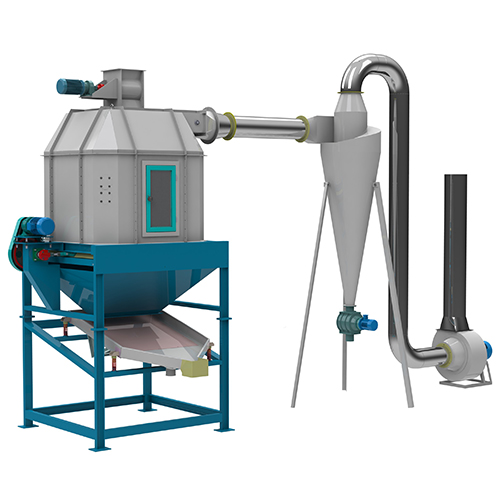

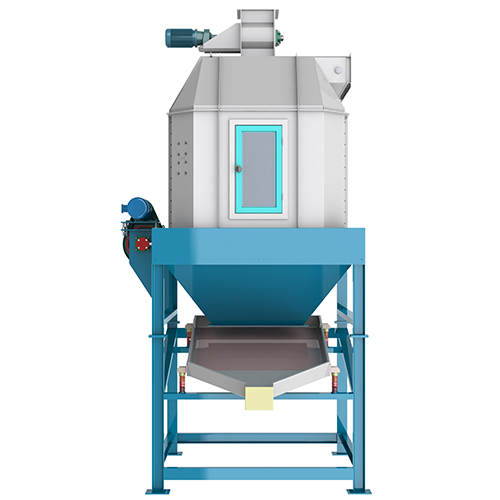

After pelletizing process,the pellet temperature will be about 70-80 degrees, and contain a certain amount of moisture. Use pellet cooler, can reduce the temperature of wood pellet,and during this process,the moisture will also reduce about 3%,to make sure the pellets can be easy storing.

FEATURES

(1)The counter flow cooler adopt counter. Current cooling principle to cool down the pellets wish high temperature and humidity, which avoid pellet cracking by the direct contact between hot pellets and cold airflow. so there is no quick chilling happens and pellet surface cracking can be prevented.

(2)Use closed unloader with large inlet area, so the cooling effect is significant.

(3)Adopts slide valve or tilting discharge mechanism with smooth and reliable motion, less pellets remain.

(4)Low energy consumption, easy to operate.

|

Model |

SKLN-3 |

SKLN-6 |

|

Inlet Air Lock (kw) |

0.55 |

0.75 |

|

Cooler Motor (kw) |

0.75 |

1.1 |

|

Vibration Screener (kw) |

0.12 |

0.12 |

|

Discharge Air Lock (kw) |

0.55 |

0.75 |

|

Bolwer (kw) |

5.5 |

7.5 |

|

Capacity (cool biomass pellets, t/h) |

2-6 |

6-9 |

|

External Dimension of Cooler (mm) |

2600×1700×3160 |

2700×2200×4225 |

Product detail pictures:

Related Product Guide:

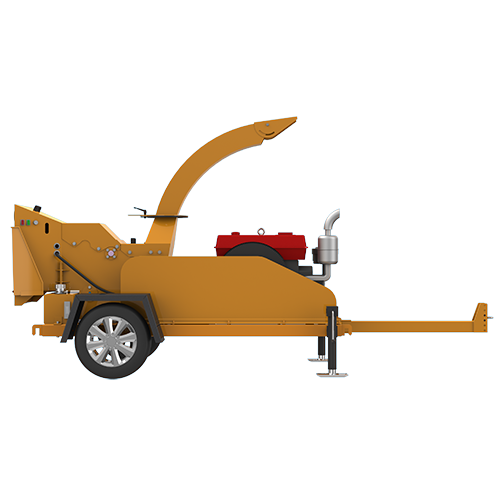

Schutte-Buffalo Hammermill Parent Company Acquires Columbus McKinnon Shredder Division | Mobile Hammer Crusher

Lynx Grills Launches New Sonoma Smoker At KBIS 2017 | Electric Branch Shredder

The customer satisfaction is our primary target. We uphold a consistent level of professionalism, quality, credibility and service for Manufactur standard Mobile Wood Shredder - Counter Flow Cooler – Shindery , The product will supply to all over the world, such as: Swaziland , Bangladesh , Sri Lanka , We strive for excellence, constant improvement and innovation, is committed to make us the "customer trust" and the "first choice of engineering machinery accessories brand" suppliers. Choose us, sharing a win-win situation!

The company keeps to the operation concept "scientific management, high quality and efficiency primacy, customer supreme", we have always maintained business cooperation. Work with you,we feel easy!