Hot sale Factory Commercial Tree Shredder - DCS-1000 Ton Bag Packing Machine – Shindery

Hot sale Factory Commercial Tree Shredder - DCS-1000 Ton Bag Packing Machine – Shindery Detail:

INTRODUCTION

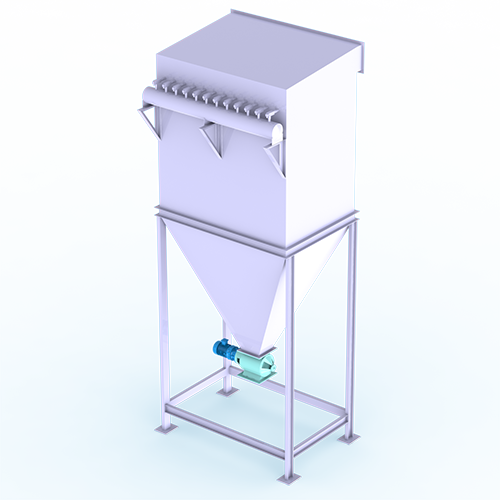

Shindery ton bag packing machine main used to pack wood pellet into jumbo bag.

Putting bag manually, after a given signal, bag holder can be done automatically, automatic lifting, automatic metering, automatic stopping, bulk bags, next round.

FEATURES

The overall structure: space saving, flexible installation;

2. Adjustable speed: the feeding mode is three-speed gravity feeding, controlled by the PLC system, and the feeding speed is adjustable;

3. Environmental protection operation: closed internal circulation system to effectively prevent dust from flying and improve working environment;

4. Reasonable structure: compact structure, small size, can be made fixed or mobile according to requirements.

SPECIFICATIONS

|

Model |

DCS-1000 |

|

Application Material |

Pellet materials |

|

Feed Type |

three speed gravity feed |

|

Weighing Range |

0.5-2tons/bag |

|

Precision |

<4‰ |

|

Packing Capacity |

15-30t/ h |

|

Voltage |

AC380V |

|

Power |

3KW |

|

Air Source |

0.4-0.6Mpa |

Product detail pictures:

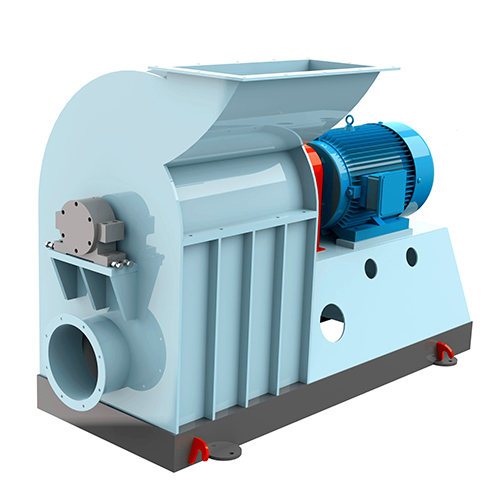

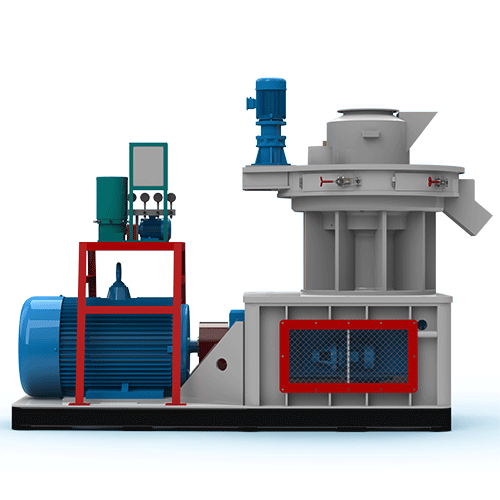

Related Product Guide:

Rambooms | Hickory Wood Pellet Machine

Vocal blogger abducted, fingers crushed : The Standard | Electric Branch Shredder

We thinks what buyers think, the urgency of urgency to act during the interests of a purchaser position of theory, allowing for much better high-quality, reduced processing costs, charges are more reasonable, won the new and outdated consumers the support and affirmation for Hot sale Factory Commercial Tree Shredder - DCS-1000 Ton Bag Packing Machine – Shindery , The product will supply to all over the world, such as: Milan , Seattle , Croatia , Strong infrastructure is the need of any organization. We are backed with a robust infrastructural facility that enables us to manufacture, store, quality check and dispatch our products worldwide. To maintain smooth work flow, we have sectioned our infrastructure into a number of departments. All these departments are functional with latest tools, modernized machines and equipment. Owing to which, we are able to accomplish voluminous production without compromising upon the quality.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.