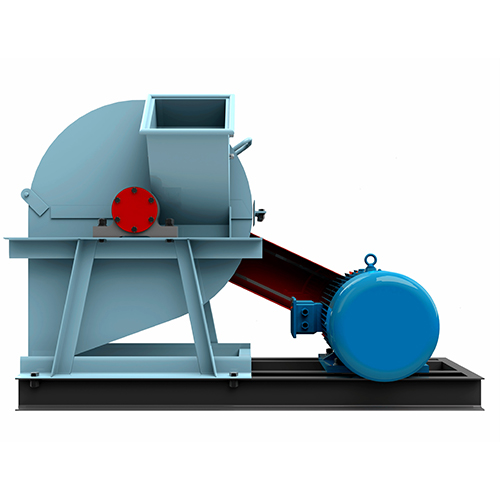

Factory source Wood Chipper Machine - Biomass Powder Grinder,Wood Flour Pulverizer – Shindery

Factory source Wood Chipper Machine - Biomass Powder Grinder,Wood Flour Pulverizer – Shindery Detail:

Applications:

The biomass grinder,wood flour machine is primarily used for superfine grinding of fiber texture material and sawdust, etc. As a kind of impact mill, it can also be used for pulverizing of non-metallic materials, feeds, agricultural products, and chemical products, etc. (Note: the Moh’s hardness of those materials should be lower than 6).

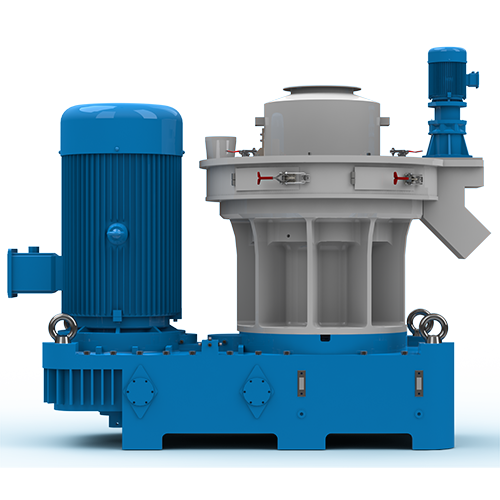

Features:

1. Energy saving: this kind of grinder can save as much as 30%-40% energy comparing with traditional grinding mill.

2. Superfine grinding: finished product fineness could be 350mesh because this grinding mill is equipped with high precision

Classifiers and super grinding chamber with 6pcs of grinding rollers.

3. Material fineness is adjustable.

4. Long service life: wear resistance materials are adopted for making wearing parts.

5. User-friendly design enables a convenient clean and maintenance.

6. Negative pressure production guaranteed a better production environment.

Working Principle:

After material is fed into grinding chamber, it will be pulverized under the shear force and extrusion force generated between

grinding roller and grinding ring. And classifier on the top of the grinder will collect qualified powder.

| Raw Material | Fineness(mesh) | Capacity(kg/h) | Screening rate | Moisture |

| Poplar Sand Powder | 80 | ≤300 | ≤98% | ≤15% |

| Poplar Sawdust | 80 | ≤250 | ≤98% | ≤14% |

| Thorns | 80 | ≤250 | ≤98% | ≤15% |

| Pine Sawdust | 80 | ≤260 | ≤98% | ≤15% |

| Cypress Sawdust | 80 | ≤260 | ≤98% | ≤18% |

| Ixonanthes Chinensis | 90 | ≤200 | ≤98% | ≤10% |

| Wheat Bran | 140 | ≤150 | ≤98% | ≤8% |

| Cassava Dregs | 150 | ≤140 | ≤98% | ≤20% |

| Bamboo Flour | 150 | ≤150 | ≤98% | ≤15% |

Product detail pictures:

Related Product Guide:

India Bakery Products Market 2018-2025 Analysis and Industry Forecast by 2025 | Parle Products Private Limited, Britannia Industries Limited, Surya Food and Agro Limited, ITC Limited, Monginis Foods Private Limited | Hickory Wood Pellet Machine

Schutte-Buffalo Hammermill Parent Company Acquires Columbus McKinnon Shredder Division | Mobile Hammer Crusher

We purpose to understand high quality disfigurement with the output and supply the top service to domestic and overseas buyers wholeheartedly for Factory source Wood Chipper Machine - Biomass Powder Grinder,Wood Flour Pulverizer – Shindery , The product will supply to all over the world, such as: Pakistan , Ecuador , Kuwait , Our production have been exported to more than 30 countries and regions as first hand source with lowest price. We sincerely welcome customers from both at home and abroad to come to negotiate business with us.

A good manufacturers, we have cooperated twice, good quality and good service attitude.