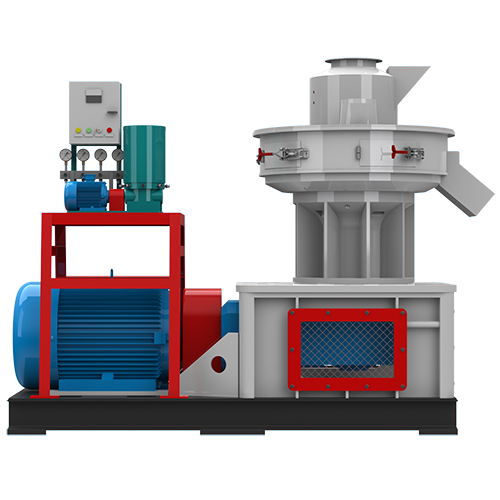

Factory Promotional Ring Die Pellet Machine - Air FLow Pipe Dryer – Shindery

Factory Promotional Ring Die Pellet Machine - Air FLow Pipe Dryer – Shindery Detail:

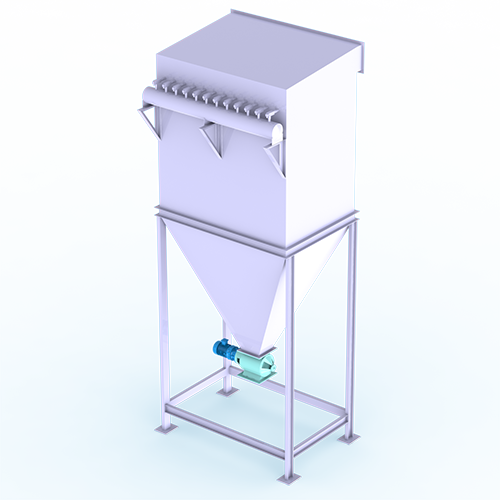

This kind of dryer is mainly used to prepare suitable moisture raw material for biomass pellet press. It is only to control the moisture of raw material at a reasonable range that can make good result of biomass pelletizing. Or the pellets will be broken because of too loose or too dry.

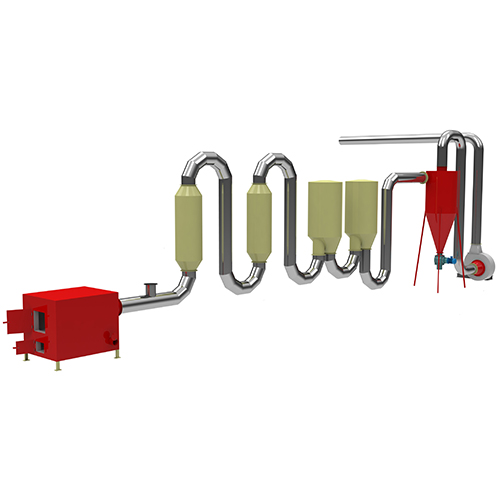

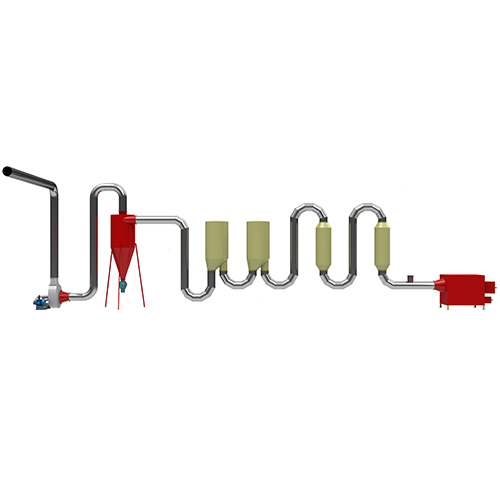

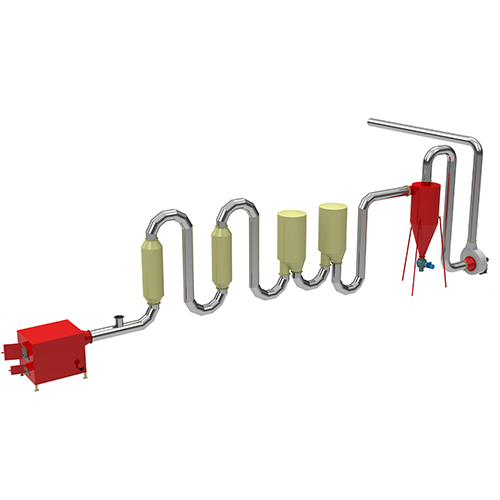

The whole system consists of fan blower, motor engine, fuel boiler, steel pipe, cyclone and air lock. In this system, wet material is input into hopper by screw feeder. Fuel furnace produces large volume of hot air. Those hot air is driven into steel pipes, mixed with wet sawdust and moved through curving pipes and drying chamber by the power of fan blower. Fast moving hot air sustains and is mixed with raw material sent by spiral feeder in the suspending state through the steel pipe; moisture evaporates as the material traverses along the steel pipe and is rendered dry at the discharge end. Humid air is continuously exhausted, thus the material is dried.

|

Model |

QHJ-1 |

QHJ-2 |

|

Dimension of Stove (m) |

1.1*1.0*1.0 |

1.5*1.2*1.2 |

|

Dia of Pipe (mm) |

219 |

325 |

|

Dia of Cyclone (mm) |

600 |

1000 |

|

Dia of Small Buffer Silo (mm) |

- |

636 |

|

Dia of Big Buffer Silo (mm) |

580 |

950 |

|

Induced Draft Fan (kw) |

5.5 |

11 |

|

Speed Adjustable Screw Feeder (kw) |

1.5 |

1.5 |

|

Total Length (m) |

11.8 |

14.6 |

|

Total Weight (t) |

2.2 |

3.2 |

|

Capacity (kgs/h) |

300-500 |

800(totally 2 small buffer silo and 2 big buffer silo,can be combined freely to realize biggest capacity or best drying effect.) |

Sawdust air flow pipe dryer

Product detail pictures:

Related Product Guide:

Rubble Master intros 120GO! tracked mobile impact crusher | Sawdust Pelleting Machine

United States Labor & Employment Attorney Hourly Rate Report 2017 | Mobile Hammer Crusher

Our organization insists all along the quality policy of "product quality is base of business survival; purchaser gratification is the staring point and ending of an business; persistent improvement is eternal pursuit of staff" as well as the consistent purpose of "reputation 1st, purchaser first" for Factory Promotional Ring Die Pellet Machine - Air FLow Pipe Dryer – Shindery , The product will supply to all over the world, such as: France , Kuwait , Muscat , We integrate all our advantages to continuously innovate, improve and optimize our industrial structure and product performance. We will always believe in and work on it. Welcome to join us to promote green light, together we will make a better Future!

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!