2017 wholesale price Wood Chip Pellet Machine - Rotary Drum Dryer – Shindery

2017 wholesale price Wood Chip Pellet Machine - Rotary Drum Dryer – Shindery Detail:

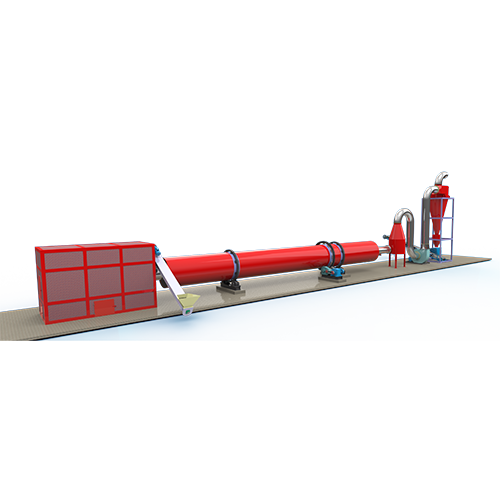

Rotary drum dryer is also called roll dryer, which is handling by bringing it into direct contact with a heated gas. The dryer is made up of a large, rotating cylindrical tube.

The dryer slopes slightly so that the discharge end is lower than the material feed end in order to convey the material through the dryer under.

The dryer can dry many kinds of materials which contain moisture, such as grain, cayenne pepper, fruit pomace, pond mud, coal, coal slurry, industrial waste, and clay stone. The dryer is also widely used in building materials, metallurgy, and chemical industry. The most outstanding advantages are high dry capacity, smooth rotation, high productivity and low energy consumption.

Through continuable improvement, the machine could meet production needs of different countries. We’ve received a lot of praises from worldwide which means that our drying machine is a popular one. Our machine is a good kind of renewable green fule machine. It’s really a perfect combination of drying and cooling.

Working principle:

Material to be dried enters the dryer, and as the dryer rotates, the material is lifted up by a series of internal fins lining the inner wall of the dryer.

When the material gets high enough to roll back off the fins, it falls back down to the bottom of the dryer, passing through the hot gas stream as it falls.

This gas stream can either be moving toward the discharge end from the feed end (known as co-current flow), or toward the feed end from the discharge end (known as counter-current flow).

The gas stream can be made up of a mixture of air and combustion gases from a burner, in which case the dryer is called a direct heated dryer.

Alternatively, the gas stream may consist of air or another (sometimes inert) gas that is preheated. When the gas stream is preheated by some means where burner combustion gases do not enter the dryer, the dryer known as an indirect-heated type.

|

Model/Item |

DIA1.2*12 |

DIA1.8*14 |

DIA2.2*18 |

|

Drum Diameter(m) |

1.2 |

1.8 |

2.2 |

|

Drum Length(m) |

12 |

14 |

18 |

|

Drum Volume(m3) |

13.75 |

35.1 |

68.4 |

|

Drum Dryer Motor(kw) |

7.5 |

18.5 |

30 |

|

Fan Machine(kw) |

7.5 |

18.5 |

30 |

|

Height (max, m) |

2.5 |

3 |

3.6 |

|

Width (max, m) |

2.2 |

3.1 |

3.7 |

|

Capacity(t/h) |

1-2 |

3-4 |

5-6 |

|

Rotation Speed(rpm) |

5.8 |

3-5 |

3-5 |

|

Air Inlet Temperature(℃) |

700 |

700 |

700 |

|

Moisture of Raw Material(max, %) |

50 |

50 |

50 |

|

Moisture of Final Product(%) |

10-15 |

10-15 |

10-15 |

Sleeve type sawdust rotary drum dryer

Product detail pictures:

Related Product Guide:

Global Hybrid Solar Wind Energy Storage Market 2019 – Siemens Gamesa Renewable Energy, ReGen Powertech, General Electric | Hickory Wood Pellet Machine

Rubble Master intros 120GO! tracked mobile impact crusher | Electric Branch Shredder

Our company promises all users of the first-class products and the most satisfying post-sale service. We warmly welcome our regular and new customers to join us for 2017 wholesale price Wood Chip Pellet Machine - Rotary Drum Dryer – Shindery , The product will supply to all over the world, such as: Portland , Mexico , Estonia , With the support of our highly experienced professionals, we manufacture and supply best quality products. These are quality tested at various occasions to ensure only flawless range is delivered to customers, we also customize the array as per the need of customers to meet the requirement of customers.

Managers are visionary, they have the idea of "mutual benefits, continuous improvement and innovation", we have a pleasant conversation and Cooperation.